1.The integral machine adopted a PLC control, featuring in easy operation. Its mechanic malfunctions can be directly displayed on the screen. The operator can easily shoot the troubles.

2.The cardboard feeder is controlled by a linear guide rail and a servo motor, so it can accurately position the paper at a fast speed.

3.Under the conveyor belt is a large-powered sucker, which can help the cardboard convey accurately and smoothly.

4.The table for the cardboard feeder is equipped with an auto stop device, which can reduce the rate of waster product.

5.The blades are durable. It is attached with a grinder characterized by easy operation.

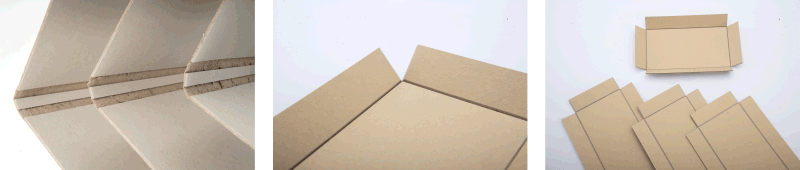

6.Wide use it can slot the cardboard, MDF, white paperboard and kraft paper etc.

| Model | AGM1000P | AGM1000P2 |

| Cardboard width | 120-950mm | 120-450mm |

| Cardboard Length | 60-450mm | 60-450mm |

| Slot Gap | 0-900mm | 0-900mm |

| Cardboard thickness | 0.3-3.0mm | 0.3-3.0mm |

| Slot numbers | 8 solts | 8 solts |

| Slotting Speed | 35pcs/min | 70pcs/min |

| Motor power | 4.5kw/380V 3phase | 6kw/380V 3phase |

| Machine weight | 1800kg | 1500kg |

| Machine Dimension | 1800x1300x1550mm | 1800x1300x1200mm |