It adopts the way of splicing three pieces cardboard to assemble a box. And its forming process employs the hot melt glue spraying instead of the paper tape sticking. It not only save the materials, but also makes the end products much solid and beautiful. No tape traces appears on the surface of finished boxes. It has multi glue spray ways, such as the point-spraying, the line-spraying etc. Which is carrying out according to the requirements of boxes.

| Model | APH550 |

| Cardboard length(A) | 80-350mm |

| Cardboard width(B) | 80-550mm |

| Side of cardboard length(C) | 80-400mm |

| Side of cardboard width(D) | 20-200mm |

| Cardboard thickness(T) | 1.5-5mm |

| Box size | |

| Length(L) | 100-350mm |

| Width(W) | 100-400mm |

| Height(H) | 20-230mm |

| Speed | 25-45pcs/min |

| Glue barrel capacity | 6kg |

| Air supply | 300L/min 0.6Mpa |

| Electrical power | 7kw/380V 3pase |

| Machine dimension | 2200×2000×2500mm |

| Machine weight | 1500kg |

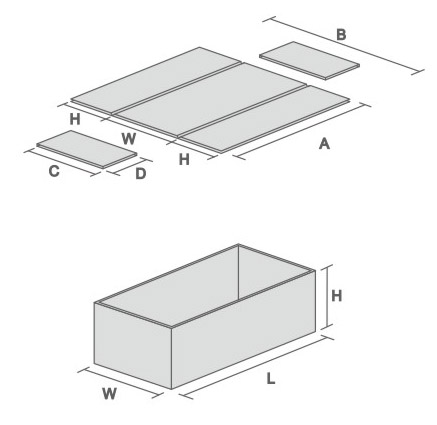

The corresponding relationship between the parameters:

L=A W=C+2T H=D+T Slotting B=W+2H Creasing: B=W+2H-4T |  |

|  |

| Imported gluing system precision 0.2mm | Big board adopts bottom-drawn non stop stacker fed controlled by servo motor. |

|  |

| Small board adopts vertical type non stop stacker fed and pressed by cylinders | Omron touch screen |