It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process;

there are features of accurate and quick positioning, and beautiful finished products etc.

It is used to make hard covers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and irregular covers etc.

| Model | HCM390 |

| Cover size(W×L) | MIN: 140*205mm MAX: 390*670 mm |

| Paper size(A×B) | MIN: 130*220 mm MAX: 428*708 mm |

| Paper thickness | 100-200g/m2 |

| Cardboard thickness | 1-4mm |

| Spine size(S) | 8-90mm |

| Spine thickness | >200g &1-4mm |

| Folded paper size | 8-15 mm |

| Cardboard number | 3pieces |

| Precision | ±0.50mm |

| Speed up to | 65pcs/min |

| Motor power | 8KW 380v 3phase |

| Air supply | 0.6Mpa 28L/min |

| Dimension | L6200*W3000*H2450mm |

| Machine weight | 5800kg |

| Cover type | 1/2/3 |

Remark:

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

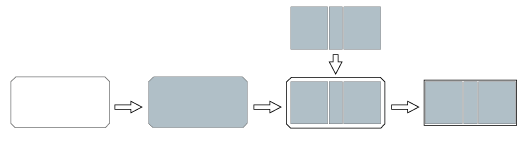

Technical parameter diagram:

|  |

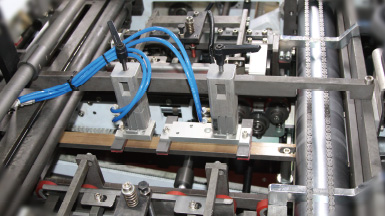

| The case size is adjusted by PLC and servo, easy to operate | Pre-stacking cardboard conveyor belt makes the production fast without stopping |

|  |

| Advanced folding technology ensures the tight edges without air bubbles. | The soft spine device, with the function of cutting, is applied to make soft spine hard covers. |

| |

| Adopt new non-stop bottom-drawn paper feeder, which efficiently avoid two pieces of papers, ensures the machine runs in high speed. |