|  |

Double rotary sheeter group Precision rotary sheeter groove is processed by imported | Electric contral part German imported Siemens PLC and the United States Emerson |

|  |

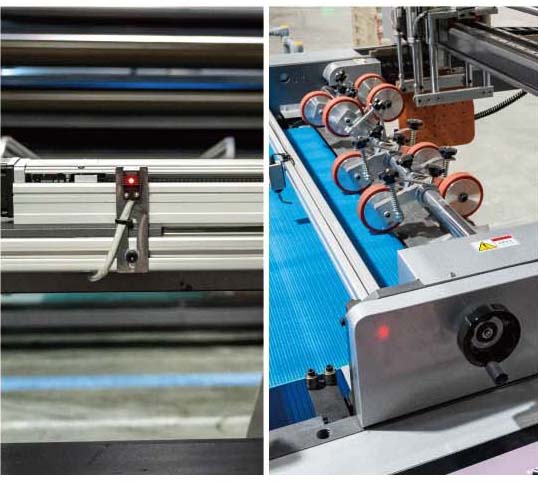

Slitting knife Top shear air knife innovative design enables pneumatic movement of | Conveying overlap part A precision structure can adjust the synchronous deceleration |

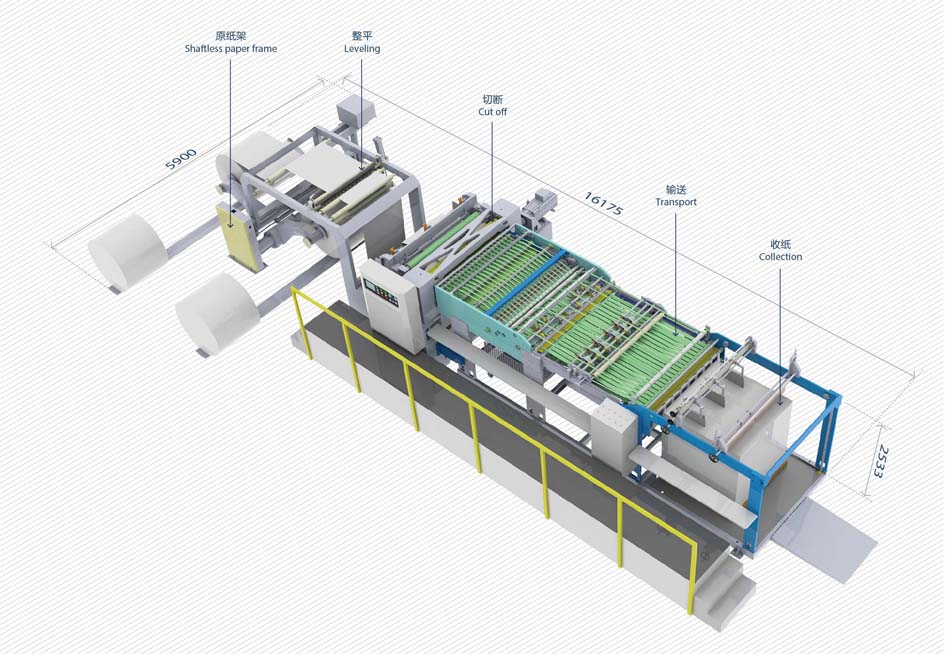

| Model | HSC-1500S/1700S/1900S |

| Reference weight of cutting-paper | 80-1000gsm |

| Model of cutting paper | Double rotary sheeter |

| Cutting accuracy | ±0.15mm |

| Gross weight | 21000kgs/23000kgs |

| Total power | 90kw |

| Cutting length range | 400-1650mm |

| Maximum scroll diameter | 1800mm(71”)Max |

| Maximum paper-cutting width | 1500mm/1700mm/1900mm |

| The request for air compressor | 0.8Mpa |

| Overall dimension | 16175*5900*2533 |

| Cutting length mm | Speed (M/min) | Speed (Cuts/min) |

| >1600 | 210 | <131 |

| 1400-1600 | 260 | 162-185 |

| 1200-1400 | 280 | 200-233 |

| 1000-1200 | 300 | 250-300 |

| 800-1000 | 300 | 300-375 |

| 700-800 | 300 | 375-400 |

| 650-700 | 230 | 328-353 |

| 600-650 | 180 | 246-300 |

| 550-600 | 160 | 266-290 |

| 500-550 | 120 | 218-240 |

| 450-500 | 90 | 180-200 |

| 400-450 | 70 | 155-175 |

1. Automatic splicer

High performance automatic twin-head paper splicer with Taiwan control system

can splice paper automatically perform out by high flexibility and long service

life suitable for base paper which grams of 80-400gsm.

2. Slitting & trimming knives automatic chnage system

APS-L eries high precision automatic positioning and slitting system matches

high precision slitting requirements. Intelligently accurately and rapedly, the

slitting and trimming knives is auto-changing by manipulator, thus greatly

improving the ability and efficiency when product variety changing. According

to different cutting requirements it can work out different cutting solutions by

coordinating with different knife, such as automatic type manual type connected

type and pressure cutting type slitting knife and electronic knife, etc.

3. Platform weighing scale system

The weighing scale installed at the lifting platform can display the weight of the paper

stack timely for recording, It uses German technology and adopts four-horizontal and

four-vertical structure to avoid scale damage and measurement errors caused by the

displacement of paper stacks.

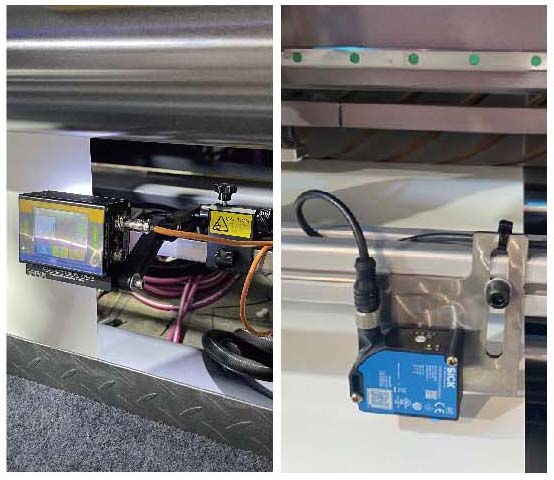

The height of the paper stack can be measured by laser rangefinder. The laser sensor emits

laser pulse, which are reflected back to the receiver by the stack, and it's height can be

calculated by the flight time of the laser pulse or the amplitude of the photoelectric signal.

4. Infrared align auto adjustment

The operator only needs to input the width in the touch screen, which can realize

the auto-alignment of the front and back paper rolls, avoid the loose and wrinkles

caused by the wrong alignment, reduce waste.This system co works with the order

auto changing system and all controlled by servo motor. It adops CCD correction

sensor and supports EPC and LPC line tracking.

5. Color code sensor

The high precision detector supplied by SICK a German brand can accurately identify

extremely fine color differences with the sensing distance tolerance up to +-5mm.

6. Dedusting rollres

The blue high viscosity roller can effectively adsorb the dust on the paper, and

then white dedust roller( driven by the cylinder) removes the dust. It's easy to

tear off the viscous film on the white one.

7. Pallet pusher

The lateral pallet auto-pusher is developed independently by HAOSHENG. The servo motor

drives the pushrod to push pallets from crossrange thus gear up for collection.

8. Auto-matreial flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor and uses the motor

drive the material transport in ultra-low postion straightly which is a modular design and

reach high degree of standardization. Hidden photo electric switch can prevent

photoelectric sensor or cardboard damage servo motor built-in to save space reversible

operation flexible adjustment basically maintenance-free.

9. Inkjet coding system

This part is composed of dedust system, high-speed inkjet system, intelligent positioning

system energy-saving LED curing system image detection system data management system

high-speed waste removal system type setting sofwware and printing software, Born for the

packaging industry.