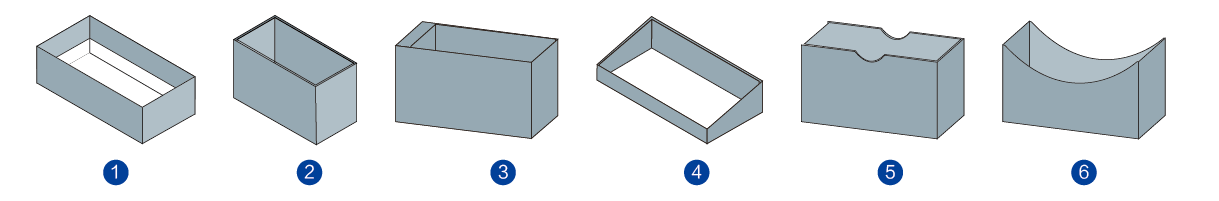

The cardboard box is pasted corners and formed, positioned onto the glued paper, pressed and wrapped. All processes are finished in one machine. It’s featured by its save-power, high speed, stability and profession of highly reliable quality. It’s applicable to make high grade package boxes, such as the electric products box, shoe box, cosmetics box, shirt box, mooncake box, wine box, cigarette box, tea box etc.

| Model | RB6040 | RB6040A |

| Box size(WxL) | Min.50*100mm Max.400*600mm | Min.50*100mm Max.400*600mm |

| Paper wrap size(AxB) | Min.120*250mm Max.610*850mm | Min.120*250mm Max.610*850mm |

| Box height(h) | 12-150mm | 12-150mm |

| Turn in depth(R) | 10-35mm | 10-60mm |

| Cardboard thickness(T) | 0.8-3mm | 0.8-3mm |

| Paper thickness | 100-200g/m2 | 100-200g/m2 |

| Precision | ±0.5mm | ±0.5mm |

| Speed up to | 35pcs/min | 35pcs/min |

| Electrical power | 16.35kw/380v 3phase | 16.35kw/380v 3phase |

| Air supply | 10L/min 0.6Mpa | 10L/min 0.6Mpa |

| Machine dimension | L6600*W4100xH3250 | L6600*W4100xH3250 |

| Machine weight | 6800kg | 6800kg |

| Paper Wrap Type | 1/2 | 1/2/3 |

Remark:

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

3. We don’t provide air compressor.

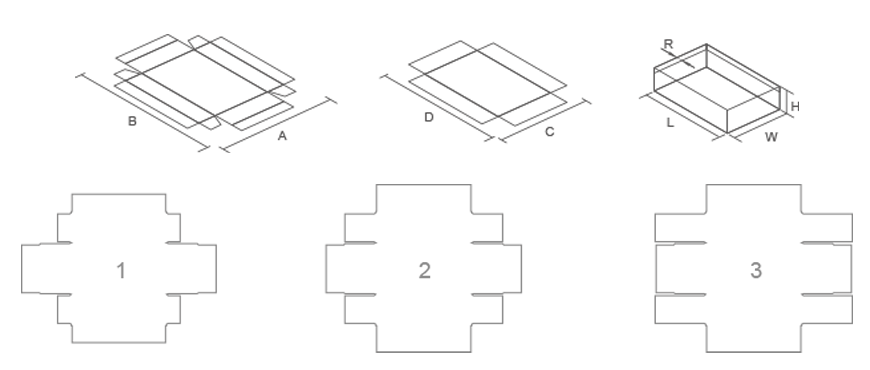

The corresponding relationship between the parameters:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

|  |

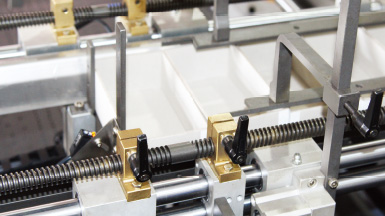

| Mechanical post-sucked type paper feeder: Adopt on-line mechanical type paper feeder with simple structure and steady running | All icons control panel: Friendly-designed all icons control panel, easy to understand and operate. |

|  |

| Hydraulic rectifying positioning device: Adopt Germany imported hydraulic rectifying system and Japanese Omron photoelectric device for positioning, which efficiently improves the precision | Auto pasting box four angles: Adopt environment-friendly tape to paste the box angles, which can paste four angles in one process with neat appearance |

| |

| Quality disc cam: Adopt durable 38CrMoAI alloy steel disc cams |