ZB1200S-430 Automatic paper bag making machine is ideal equipment for large batch paper bag produce. It adopts mechanical, electrical, optical and pneumatic technologies, combined with several patent technologies. After printing and die cutting/creasing, the machine automatically feeding sheets, register, top folding (or without top folding), tube forming, gusset forming, bottom folding and open, bottom cardboard insert(square bottom), gluing and compaction output. The machine take the advantages of new variable transmission technology, together with transverse and vertical creasing and bottom pulling systems to realize the traceless bag bottom closing. Thanks for the PLC and frequency control system, the machine can be operated by multi points and single remote control. With the advantages of high quality bag forming and high efficiency, the brand new ZB1200S-430 is leading equipment in the world.

Art paper, white board and ivory board need lamination. All paper including Kraft paper need die-cutting in advance.

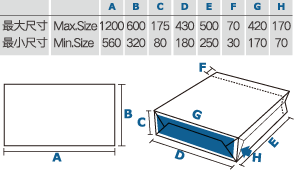

Parameter:

Max. sheet (LX W) | 1200x600mm |

Min. sheet (LX W) | 560x320mm |

Sheet Weight | 190g-300g/m2 |

Bottom Width | 80-175mm |

Bag Width | 180-430mm |

Top Folding Deepth | 30-70mm |

length of bottom cardboard | 170-420mm |

width of bottom cardboard | 70-170mm |

Bottom card thickness | 250g above |

Total Power | 30kw |

Machine Size | 14000x8000x1800mm |

Speed | 50-80bags/min |

Total Weight | 15T |

Glue Type | Water soluble cold glue |